ZeFF – Zero emission Fast Ferry

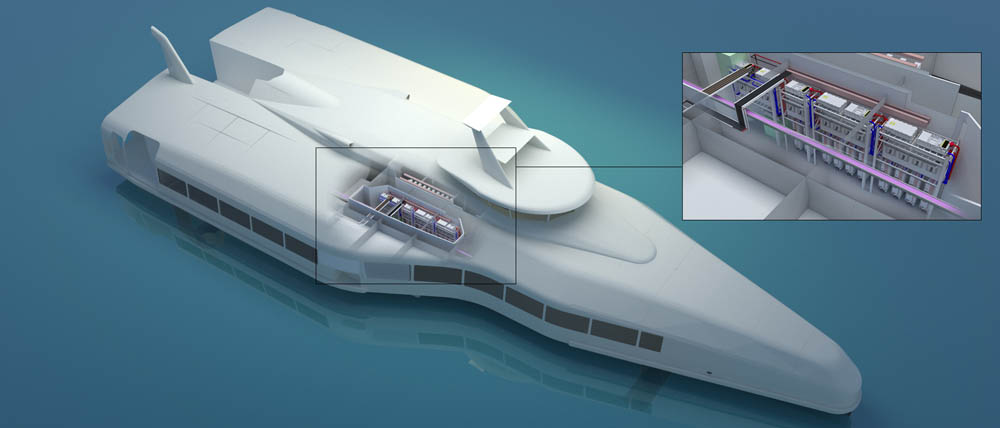

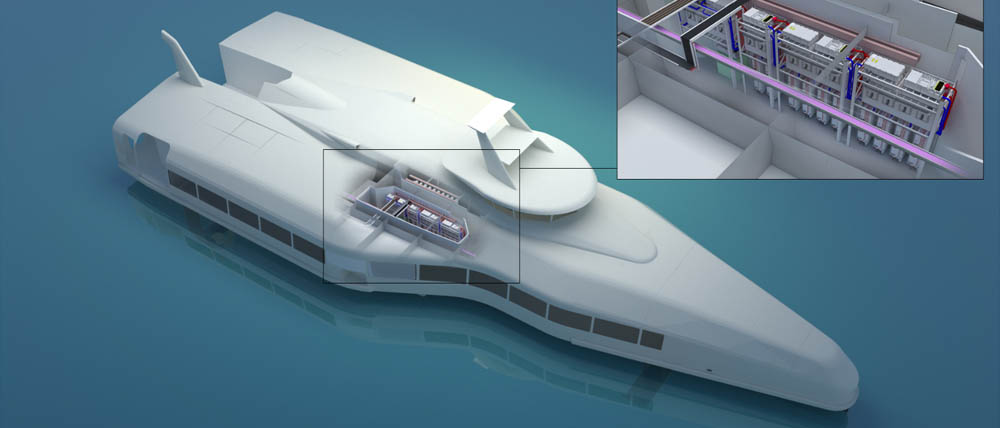

BEIN Engineering was awarded the responsibility for the design and development of the power electronic systems aboard the zero emission concept vessel ZeFF, on behalf of Selfa Arctic. ZeFF is an exciting concept for the high speed ferries of the future. The ambition is to launch the first hull in the near future. The vessel is designed to be fully foiling at transit speed, and has a zero emission propulsion system.

The Norwegian parliament has decided that all ferries and high-speed commuter vessels in public service must have zero emissions in the future. However, there is no available technology that realizes this ambitious goal, while not reducing the quality of service. Norled has been allocated government funding for development of such technology, and has therefore initiated concept design in consortium with Selfa Arctic, LMG Marine, Servogear and Hyon under the Pilot-e banner.

The design criteria for ZeFF:

- >30 knots Transit Speed

- Minimize viscous resistance by lifting the hull completely out of the water

- Sail without emissions of CO2, NOx or Sox

- 100 – 300 PAX

- Superior passenger experience

Ola Elvestuen, the Minister of Climate and Environment

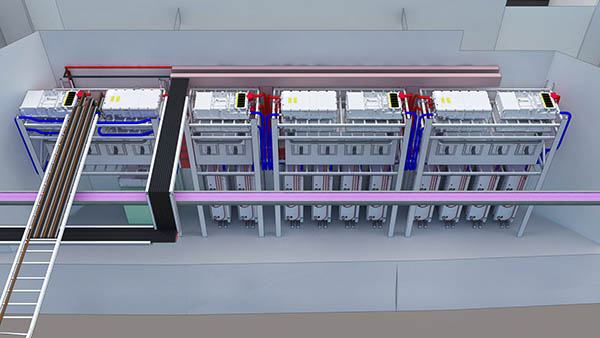

BEIN Engineering was awarded the design of the power electronics for the concept vessel, on behalf of Selfa Arctic. The goal has been to develop a compact, light weight solution, while maintaining efficiency and flexibility with respect to different energy storage systems. The system is designed to be modular; easily scalable, and easy to incorporate in other concepts as needed in the future.

In this particular concept, the focus has been on hydrogen and batteries as energy storage mediums, which is new technology in the field of high speed vessels. The need for a close relationship with the fuel cell supplier, PowerCell of Sweden, rose quickly, encouraged by the hunt for an optimal solution for the application. Thus, multiple visits to the supplier led to better insight in the functionality of the fuel cells, and the challenges involved for the electrification of such a vessel. Close relations with the Naval Architect was kept during the hull design process, in order to communicate design criteria such as weight, center of gravity, cable routings and volume. The design and specification for top level ship systems (IAS, PM/EMS, Flight Control System), with interfacing in mind, has also been important, to provide a solid foundation for the next step(s) in development.

We have experienced several exciting challenges during the project, in which the majority of our staff have been involved during brainstorming, not only the department of electronics and control. The department of mechanics has designed lightweight solutions for the structural part of the installation, while the department of 3D-vizualisation has developed new solutions by way of geometric optimization of component locations and cable routings. In the electronics department, we have explored new concepts for floating ground DC networks in carbon fiber superstructures, taking the varying conducting properties of the composite into account. Electromagnetic Interference (EMI) has been of the essence in order to ensure safety and reliability during operation. We are proud to claim that we have developed a design that follows known class rules, that can be guiding for new rules and regulations in the future.

The concept ferry

Power electronics

More articles on zero-emission technology and the ZeFF project: ZeFF: Towards zero emission fast ferries and HYON AS: Awarded Grant in Two R&D Contracts for Zero-Emissions Maritime Transport using Hydrogen Fuel Cells