What does a hairpin have to do with splicing cables?

A damaged cable, perhaps as a result of contact with an anchor or heavy fishing gear, can lead to interruptions in the power supply or communication. Often this affects functions critical to society and there is a need to have these repaired quickly. There have been several cases of damage to submarine cables in 2022.

For example, NRK reported on 20 October this year about a damaged communication cable outside Shetland. At a time when the spotlight is on electrification, more cables are being installed with the aim of getting a stable supply of electricity to consumers.

Large power cables ensure the import and export of electricity between countries. Smaller cables connect electricity production from, for example, wind farms. The aforementioned cables are exposed to damage as a result of activity at sea, and accidents with these often have major consequences for consumers. Read more about cable repairs here: https://bein.no/kabelreparasjoner/

With the aim of having the damage repaired as quickly as possible to minimize downtime on the systems (note that diesel generators are often the emergency solution in many places) good planning/project planning is required as well as the right available vessels and equipment.

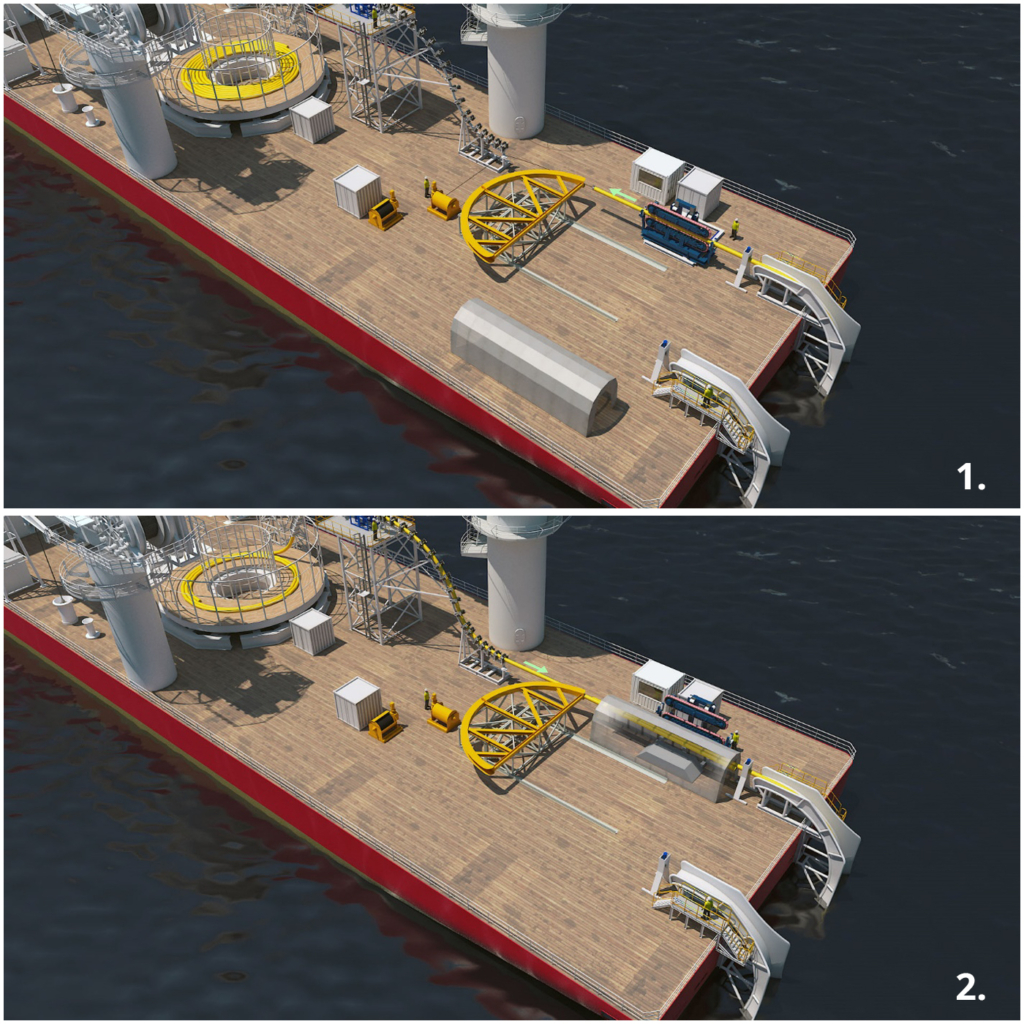

In short, a cable repair typically takes place as follows:

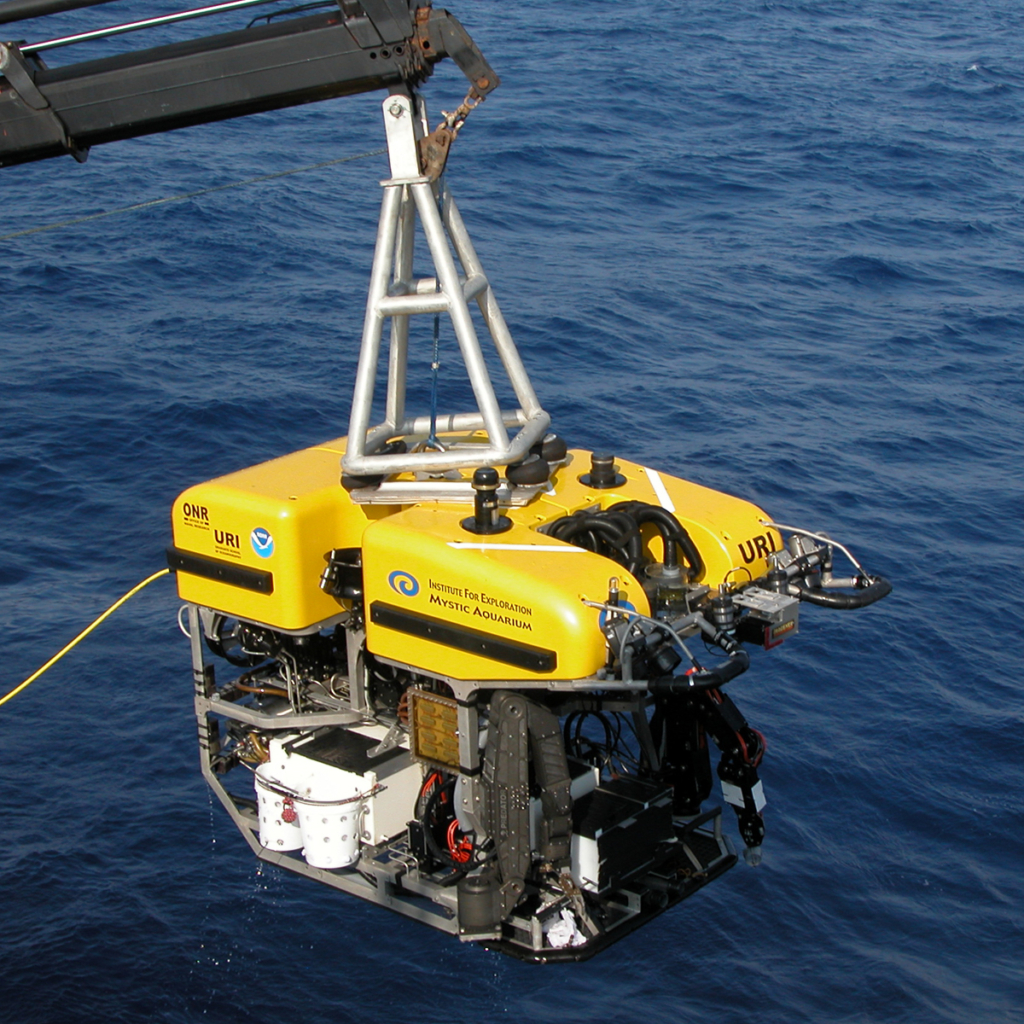

The damage to the cable in question is located and the cable is cut with, for example, an ROV if the cable has not already been completely severed. With special equipment, a cable end is lifted up to a suitable vessel, typically using a winch and adapted clamps. On board the vessel’s deck, damaged cable is cut away and sealed, so-called “cut’n seal”, before it is laid down on the seabed again.

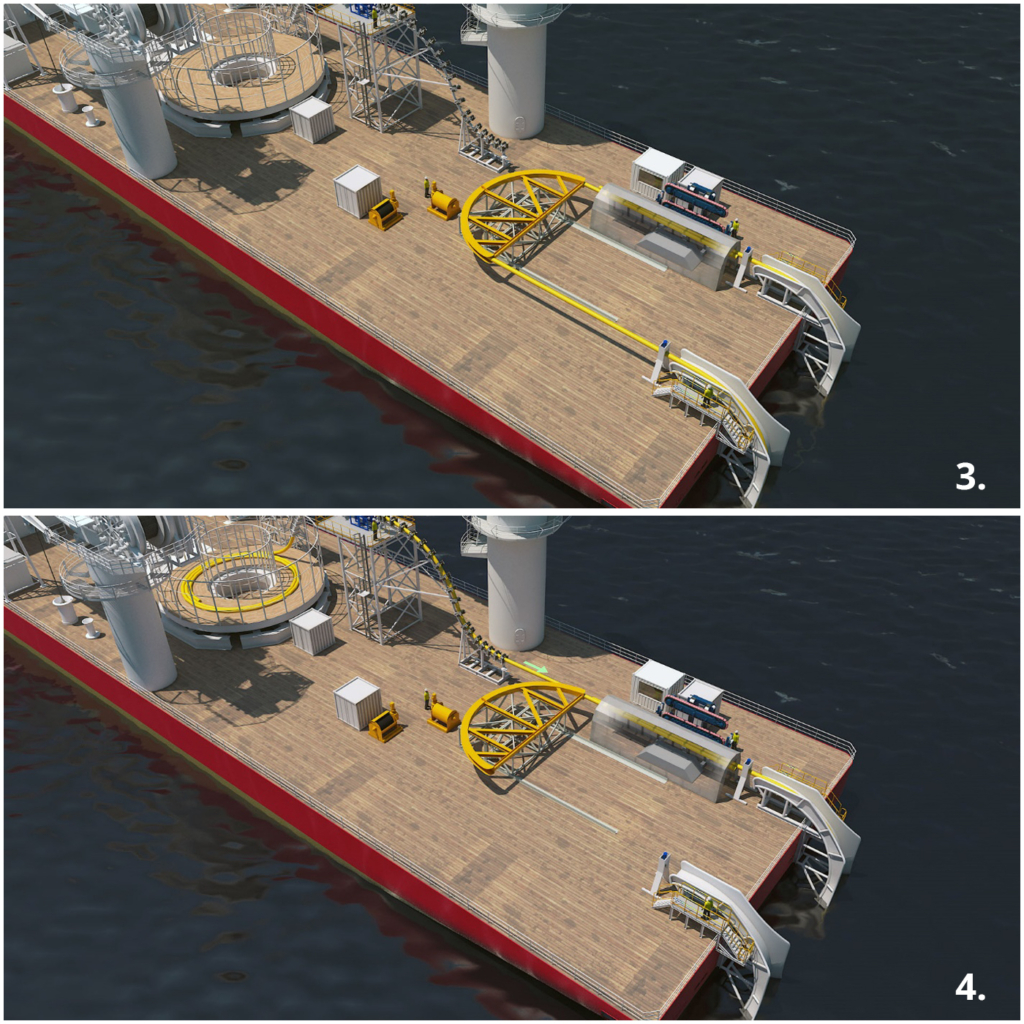

The same operation is repeated for cable end no. 2. The damaged part is cut away and it is made ready to splice in a piece of corresponding spare cable. Extra cable is required to compensate for the part of the cable that is damaged and cut away, and for the relevant water depth. The cable can be relatively long and is temporarily stored on a cable carousel.

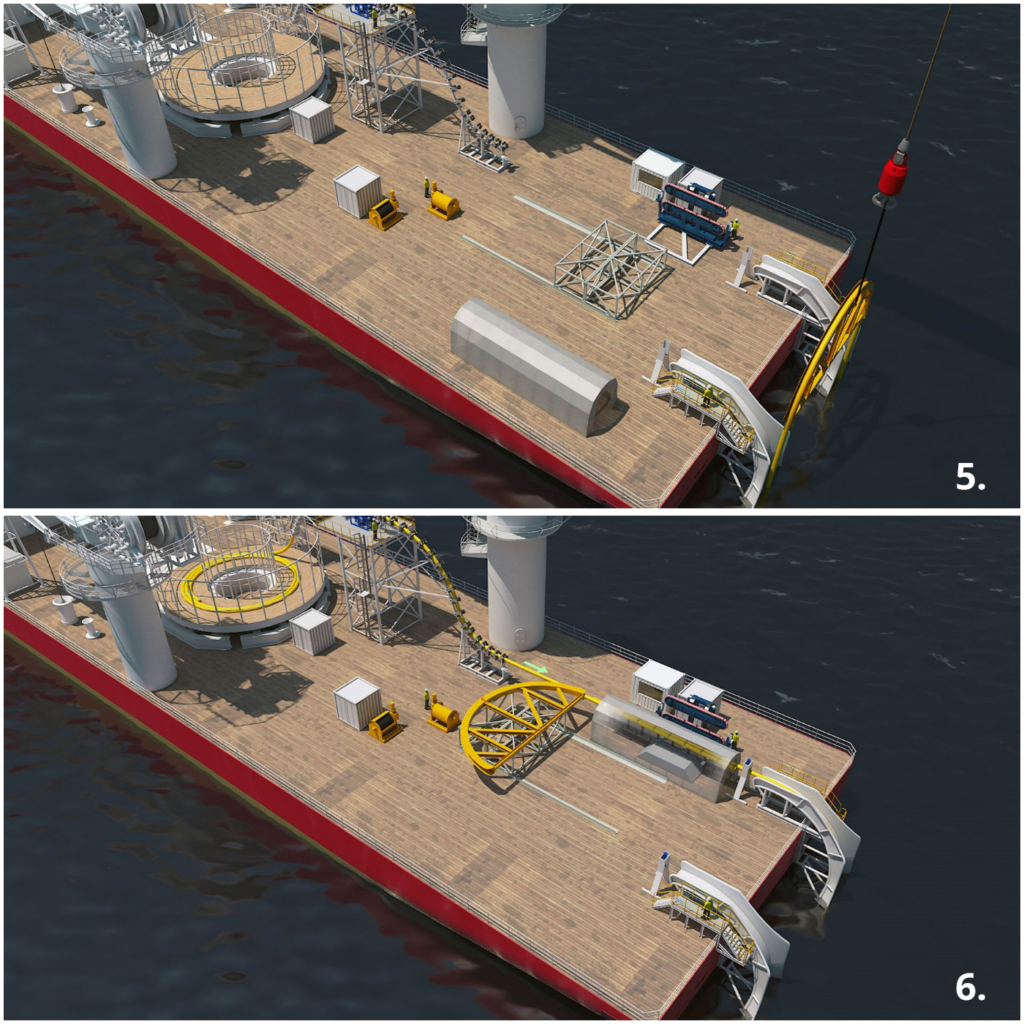

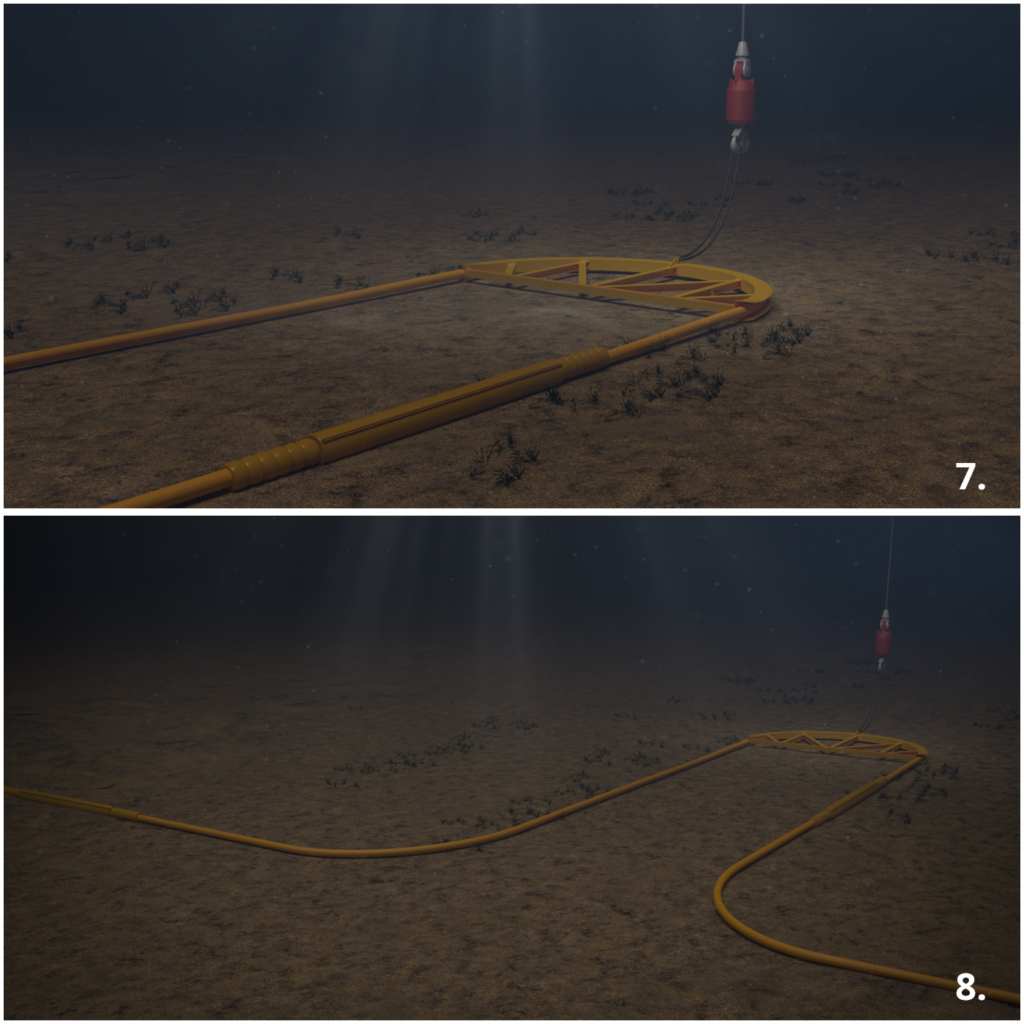

The splicing operation of the cable is often a painstaking process that requires experienced personnel from the relevant cable manufacturer. The splicing operation itself usually takes a few days. When the first joint is completed, it is laid on the seabed together with the new spare cable. Spare cable is added until you get to the cable end no. 1 and can pick it up on the deck.

When cable end no. 1 has been picked up on deck again, you have 2 cable lengths hanging from the ship – the new spare cable and cable end no. 1. Now you have to join these together in a joint no. 2.

With the right equipment and set-up on board the vessel in question, the jointed cable is lowered to the seabed using a cable arch https://layback.no/and it is then that you can clearly see the comparison between a hairpin and such a cable joint.

Hence the word – hairpin joint! 😊