ANALYSIS AND CALCULATION

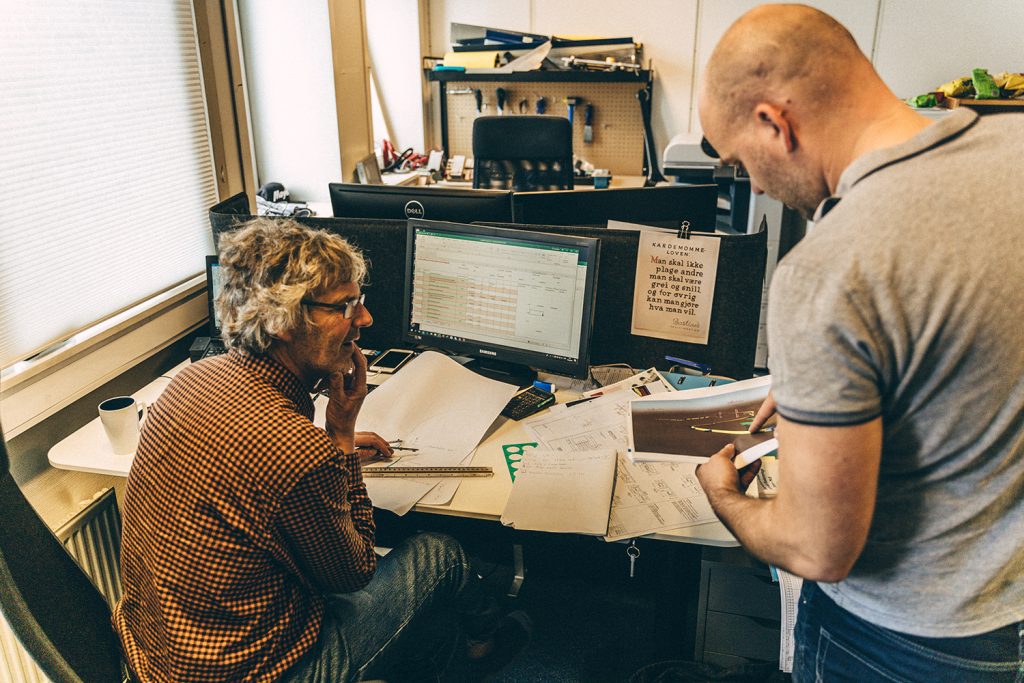

To document that something works as planned before it is built, tested or before an operation is performed, the use of engineering skills is an effective tool. Based on sketches, drawings, descriptions and models, an engineer can perform calculations to check that something is floating, is stable, that something does not break or collapse, that over time, loads do not spoil anything, etc.

The results from analyses and calculations can be used to select materials, optimize structures, define the most suitable methods for installation, streamline consumption, in risk assessments and for documentation in connection with certifications and approvals of products and installation methods. The level of detail of an analysis is usually related to the risks associated with the final result, and cost – benefit.

BEIN Engineering is well acquainted with methods and tools that allow us to assist in most stages of the project, in several disciplines and we can make recommendations for a most cost-effective process.

At BEIN we have experience with many different types of analyses and calculations.

Here are our key qualifications in analysis and calculations summarized:

- Statics and strength calculations

- Pressure Equipment

- «Reverse Engineering»

- Marine operations

- Hydrodynamics

Statics and strength calculations

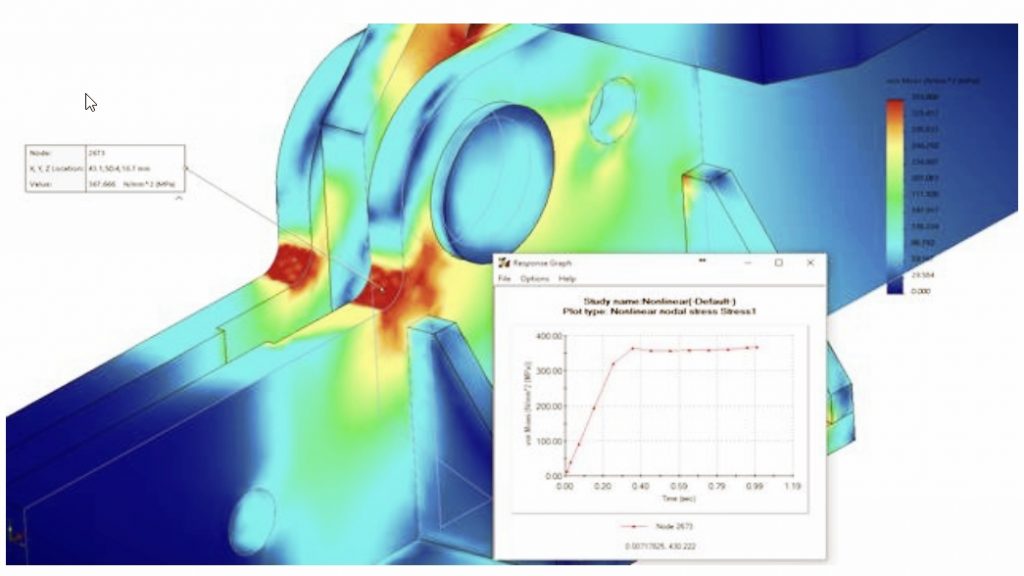

Projects and assignments often start with simple hand calculations or the use of programs such as ColBeam to get a rating on what works and what doesn’t. This is often documented in programs such as MathCAD or MS Excel. It is often sufficient at an early stage of the project and for less complex structures. Furthermore, it is natural to use modelling, simulation and analysis that are more adapted to the environment and application. For detailed strength calculations and fatigue analysis, Finite Element Analysis (FEA) is used for linear and nonlinear considerations. Such analyzes can also be used for simple beam structures. For complex beam structures with a large number of beams and loads, it is natural to use dedicated beam calculation programs such as STAAD Pro or similar. Often, combinations of these methods are needed to adequately document structural integrity.

Pressure Equipment

We assist our customers with calculations of pressure equipment. These are calculations that are strictly governed by regulations reduced by the Pressure Equipment Directive – PED. In this work, we usually start the same as for other structures with hand calculations, simpler analysis tools and we use the software Integraph Visual Vessel Design or equivalent for more detailed analyses. Knowledge and experience with the latter make it possible to carry out checks of small and large pressure vessels and other pressure equipment in line with current standards. This provides good flexibility to efficiently analyze with different material qualities, pressure and temperatures. Visual Vessel Design also makes it possible to perform fatigue analyses and take into account a number of other environmental conditions. The software provides a solid documentation basis, which is important for CE certification of the equipment.

Reverse engineering

Most often, analyses and calculations are included in a study and/or detailing phase in the project. Sometimes reverse engineering is performed which is a working methodology where one with the starting point of a finished product or solution documents through measurement, photo, 3D scanning and reporting. This is analyzed and optionally replaces all or part of a product development process. BEIN has experience with technical documentation of existing facilities or operations where we have assisted with photography, surveying and 3D scanning. This has been used further as a starting point for P&ID drawing, layout drawings, design of new equipment or in connection with the implementation of other adjacent components. For example, we can use the deflection of a structural element to document the loading on a structure. In these processes, we can use simpler “hand calculations” or more advanced software. Again, it depends on cost-benefit, documentation requirements and risk.

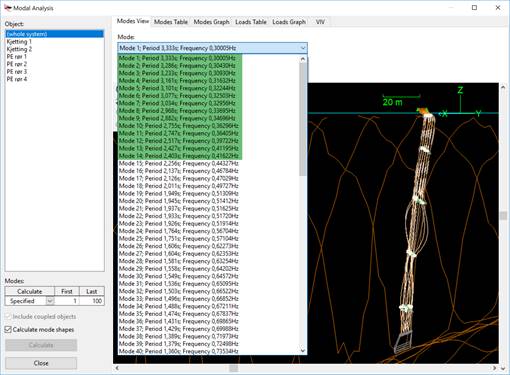

Marine operations

At BEIN Engineering we have extensive experience from various marine operations with both theoretical and practical approaches. We have particularly good knowledge from preparations and implementation of umbilical and cable laying, as well as marine lifting operations. Often, preparations for such operations include static and dynamic analyses related to the product to be installed, handling equipment and supporting structures. Calculating accelerations on board a vessel is usually necessary input to lifting analyses to ensure a safe installation that avoids unfortunate consequences for personnel, the product being handled or the equipment used. BEIN Engineering uses, among other things, the software Orcaflex as a tool in connection with installation analyses. Worth mentioning is that we have developed a method to transfer complicated structures from construction programs to Orcaflex to make the workflow easier and more transparent. This has previously been a time-consuming process, but it can now be performed with some simple conversions. Orcaflex is a useful analytical tool for the extraction of pipes, cables and umbilicals. In analyses in connection with lifting operations from boats through splash zone, Orcaflex is also a valuable tool. Simpler but often satisfactory, calculations using spreadsheets based on typical DNV-GL regulations are also a good conservative approach.

Hydrodynamics

At BEIN Engineering, we have extensive experience with the marine environment and perform analyses and calculations on structures and systems exposed to demanding environments.

As mentioned earlier, we have good experience with cable analysis and the use of Orcaflex for numerical analysis.

Other analyses and calculations

Occasionally, special types of calculations and analyses are required. This, for example, relates to fluid flow (Computational Fluid Dynamics (CFD)), VIV analyses (Vortex induced vibrations), in connection with electrical installations and more. BEIN Engineering has experience with deliveries of a number of different analyses and calculations for different purposes. We have a number of partners who can also assist as needed.