DESIGN AND CONSTRUCTION

BEIN Engineering’s personnel have extensive experience in the design and planning of technical solutions and products. The work is executed through systematic and creative processes. In the product development we go from idea phase through detail design and to final tested and documented product. Here are some of the things we can contribute with, in the development of creative solutions for your operations:

- Evaluation of existing concepts.

- Idea development for new detailed designs.

- Development of related equipment.

- Procedures and documentation.

- Follow-up of field operations.

- Product design from concept to final and tested product

In the early phase, we use cost-effective visualization tools to illustrate and animate ideas, making them easier to share with others. This is especially effective in sales and within application processes. This is also effective in studies, whether in connection with mechanical design, the design of systems for management and control, visualization of buildings and facilities, marine operations, or other technical solutions.

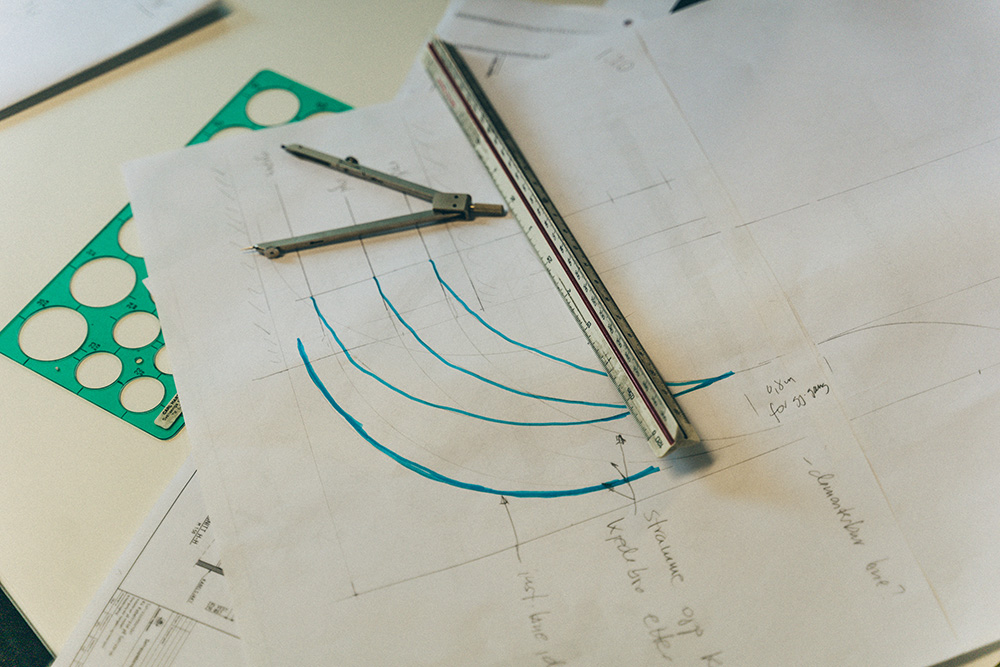

BEIN’s staff have excellent skills in hand drawing as well as in 3D modelling using the 3D Studio Max visualization tool at an early stage of the project. These 3D files are easier and faster to handle and modify than classic CAD models, as they contain less information. This makes them especially suitable for experimenting with different designs and testing interfaces. Existing 3D models from software such as Autodesk Inventor, Solidworks, drawings in DWG format from Autodesk AutoCAD, DraftSight and hand sketches, can also be applied as the sole basis and/or in combination with new models. Images of environments and/or maps can also be implemented. The models are textured and rendered so that they portray a sense of reality through still images as well as animated films. They can also be presented in the form of Virtual Reality (VR) or Augmented Reality (AR). BEIN has equipment and facilities for presentation in VR. Software such as Lumion, with real-time rendering, can be used to give the quickest impression of the possibilities, which is cost-saving. But in this case, the degree of detail in technical solutions can be somewhat more limited. The 3D models from the visualization tools can also be easily transferred to 3D prints of physical objects.

BEIN provides 3D printing in all qualities and can also deliver prototypes in actual material grades and with the required tolerance requirements.

In close consultation with the customer and other stakeholders, we prepare specification documents prepared in relation to the environment in which the product is located or the operation is supposed to take place, to any interfaces with other facilities, to any interactions with people, to any loads the product may be exposed to, and to manufacturing methods, cost requirements, HSE and aesthetics. This is conducted in compliance with relevant standards, such as Eurocode, DNV, NORSOK, and statutory requirements specified in the Working Environment Act, the Machinery Directive and the Pressure Equipment Directive. We have experience with CE marking of machinery, pressure vessels and pipes – and this is important to take into account in the early phase as this can affect the choice of materials, required design and costs.

Calculations, such as manual calculations and simpler 2D and 3D CAD models, are also used to check structural strength, view proportions and test interfaces, among other things. We do this to separate the good ideas from the less advantageous concepts before using too many resources on them. BEIN has long experience in the evaluation processes for concept selection. We have our own developed system for this, which also includes risk assessment for products and solutions.

After selecting a concept, the process moves to the detailed design phase, or “detail engineering”. BEIN typically produces 2D and 3D models that are used for detailed analyses, where we work to identify the concept that will comply with the requirement in the specifications. This phase includes structural calculations, detailed interface checks, dynamic analyses, and calculation of reaction loads for hydraulic, pneumatic or electromechanical components and systems. BEIN works with tools such as Solidworks, STAAD Pro, Mathcad, Visual Vessel Design, Colbeam, Orcaflex and others. By detailed design and planning, or “detail engineering”, we mean a theoretical approach based on physics, mathematics and experimental data that allows our engineers to verify whether a product or technical solution meets the design requirements even before the design has been completed. This work is typically documented in design reports or procedures for operations.

Apart from that, test procedures are often established for further physical testing to reveal any deviations from the theoretical process. BEIN has extensive experience with load, functional, friction, pressure and system testing of various machines and mechanical solutions, cable handling equipment, umbilicals and risers, underwater tools, tanks and load-bearing structures.

Fully tested and in some cases modified solutions or products are sent on to operations or manufacturing. For this we use our quality assured procedures and production drawings. We are ISO 9001 certified, and have a number of manufacturers and suppliers both in Norway and abroad, who are qualified to undertake the processing of various metals, structural welding, assembling and testing. For larger structures where there is a need for transport by sea, manufacturers with berthing facilities are often our preferred partners.

Our multidisciplinary and experienced team has good knowledge of project management. We assist with this whenever requested by the customer during project implementation. We can deal with products and solutions for marine operations such as heavy lifting, installation, decommissioning and underwater technology, as well as with onshore industrial works, energy, engineering, transportation, construction, research or development works.

Sometimes we also perform reverse engineering. This is a working methodology which involves taking a finished product or solution and documenting it through measurements, photographs, 3D scans and reports before proceeding to analysing it and to possibly change the product development process completely or parts of it. BEIN has experience with the technical documentation of existing facilities or operations where we have assisted with photography, surveying, 3D scanning, and where all this has been used further as a starting point for preparation of P&ID (piping and instruments diagram) drawings, layout drawings, the design of new equipment, or in connection with the implementation of other adjacent components.