AVIATION FUEL

BEIN has assisted in a number of projects related to aviation fuel supply facilities at various airports. In these projects, BEIN has created documentation for existing tank facilities and delivery systems and worked on modifications and upgrades. Our projects include everything from the supply of tanks and piping systems fire safety plans, site drawings, and P&ID diagrams. As part of our documentation work, BEIN has supplied images and video documentation for components and systems.

- Project management, planning and administration for installation and manufacturing.

- Preparation of specific procedures such as filling or sampling.

- Follow-up on site by project engineers.

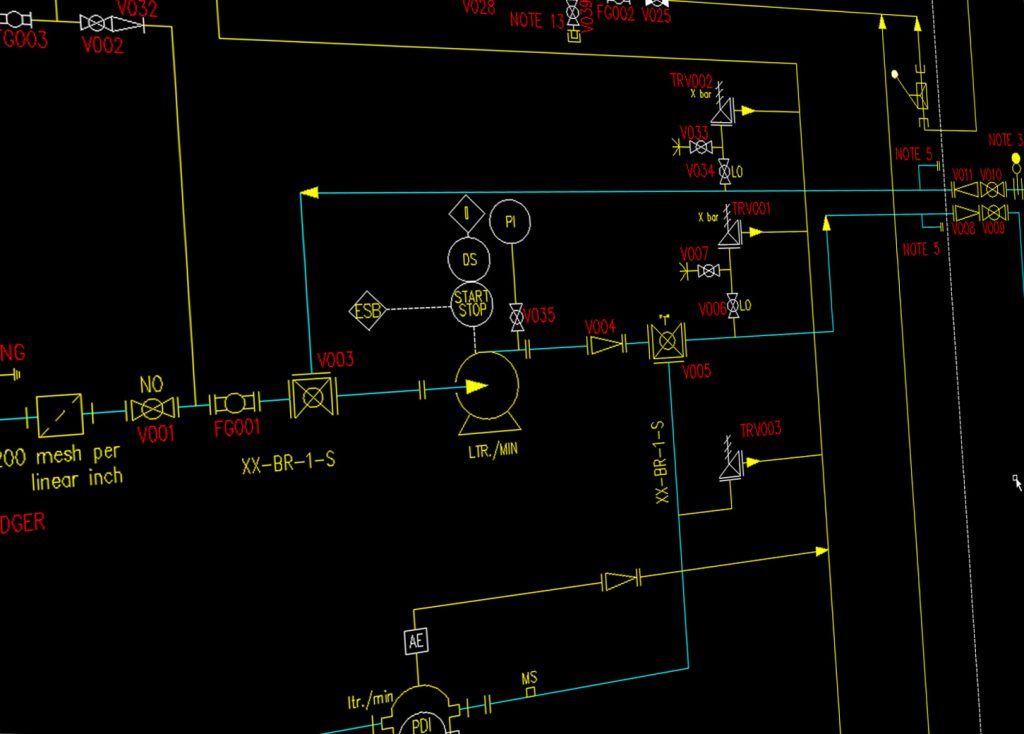

- Preparation of fire safety plans, site drawings, and P&ID diagrams.

- Visualization of new and existing facilities.

- Delivery of tanks, pipe systems and other equipment.

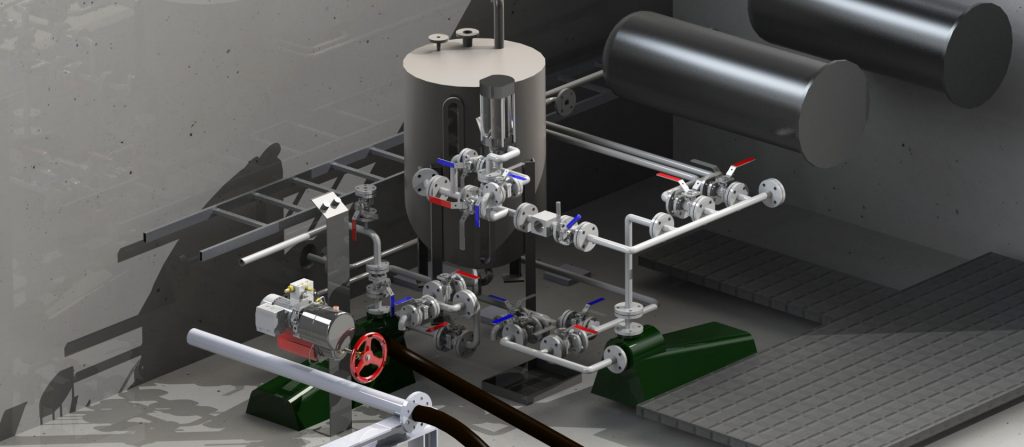

Aviation fuel must be checked regularly for water and other types of impurities. This check is performed using a sampling system. The tested fuel is transferred to a tank known as a Product Recovery Tank (PRT). If the fuel is approved for further use, it is then passed through a filter and returned to the main tank of the plant. BEIN has experience in the development, design, and preparation of technical documentation for fuel sampling systems as well as for associated tanks.

Sampling systems are most often combined with a fuel dispensing cabinet for aviation fuel. The dispensing cabinets contain; pumps, pipes, filters (particle filters, separator elements and monitor elements), valves, flow meters, overhead couplings, underwing couplings, motorized hose reels, ground terminals, wires, fire extinguishing equipment, and electronics. All to ensure that the plant can be filled, that the product can be tested regularly and that the plant operator can fill the aircraft safely.

In most cases, we begin with a P&ID diagram prepared by ourselves in collaboration with the customer before modelling the system in 3D. The 3D model is a great way to get an overall view and determine where best to place valves, sight glass and other equipment in a way that will make the plant optimally suited for the operator.

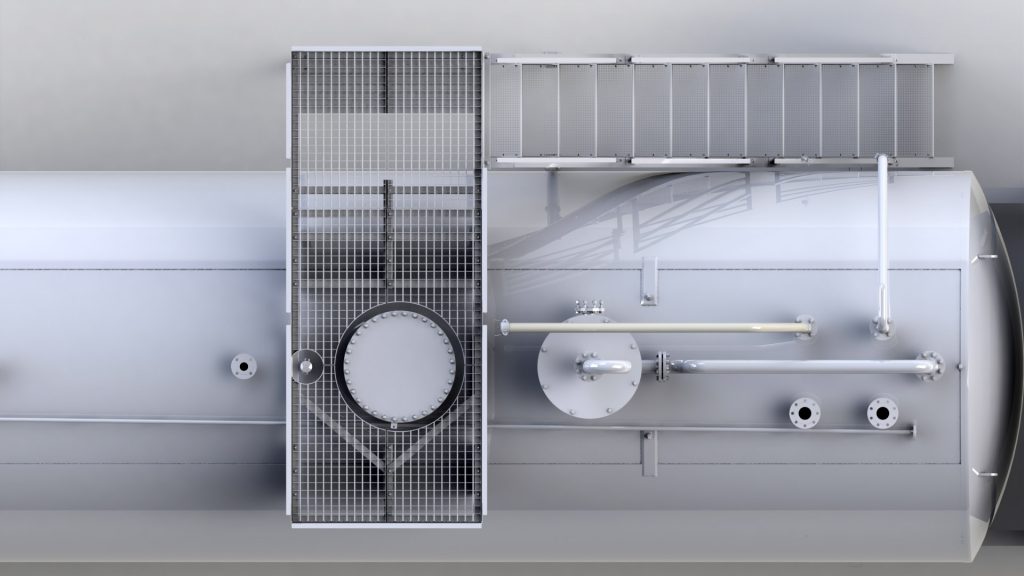

In order to meet the authorities’ new requirements for overfilling barrier, BEIN has helped to develop overfill tanks for a number of airports in Norway. We base our design on customer needs, regulatory requirements and applicable standards. BEIN designs and supplies other equipment, such as: various frame structures, access platforms, tanks, control equipment and control systems, etc. Together with our manufacturing and component partners, we always make sure we find the best solutions for our customers.

BEIN has good experience in the customization of electrical and control systems, based on rapid prototyping. Whether your project requires a fast and easy controller and driver for a DC motor, or complex systems for controlling and operating light, sound or mechanics, BEIN can help find the best solution.

CE marking is required by law for many of the above applications. We can prepare related technical documentation such as risk assessments or declarations of conformity; and we have extensive experience in preparing procedures, fire safety plans, site drawings and P&ID diagrams.

Using sketches, 3D scans or similar, BEIN can turn ideas into finished construction and manufacturing drawings. We use 3D programs in our work from the very beginning. The 3D models we produce can also be used later in the work process, in visualization programs and in VR/AR. We start with 2D drawings, where we can include cutting lists for materials, welding data and information on bolts for construction. In the process of our work, we handle most file formats. STEP, DWG / DXF, as well as files from AutoCAD, Inventor, Solidworks, Navisworks and others. 2D AutoCAD is used for P&ID, fire safety plans and site drawings.